|

SUMO

|

|

« on: February 04, 2009, 12:18:28 PM » |

|

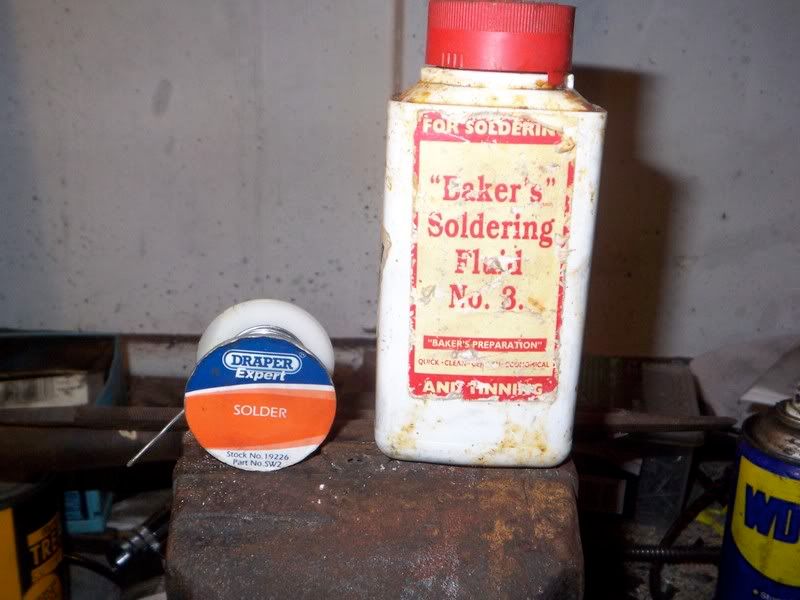

dont know if theres any etiquet posting techs but i figured this might be some help to someone here too - a friend of mine in america asked me to show him how to make up cables so he didnt have to either pay out for custom cables or have yards of spare on his bike. its fairly self explanitory, but like all stuff - if nobody has ever told you then its a black art. i buy the longest universal cables available and cut em down [specific brake or clutch, get the right thickness] solder and bakers fluid  making cables use a propper old fashioned soldering iron not a pissy little electric thing  making cables feed the cable through the nipple and splay the ends out so i cant fall / pull out  making cables heat from the side with the soldering iron - for this job you dot need to put solder directly onto the iron  making cables drop in some bakers fluid down the splayed end - if it bubbles brown then your cable is dirty and needs cleaning thorougly [just heat it on the iron and dip it in bakers fluid, repeat untill clean bubbles] or your soldering wont be strong enough. feed in solder down the hole till it fills up and you can see a tiny little bit out of the cable end of the nipple [ok so im running out of hands so you get the idea  making cables dress off with a file and there you have it - one new cable to your exact length. done like this you end up with a wedge of solder inside the wire itself. basically means you can pull it out through the smaller hole  making cables can save a small fortune over time doing this yourself in a safe way. |

|

|

|

|

Logged

Logged

|

|

|

|

morrag

Hero Member

Karma: 49

Posts: 2875

Carpe diem!

|

|

« Reply #1 on: February 04, 2009, 12:30:21 PM » |

|

Ah, takes me back to my youth when I had to do same for all cables as there were very few "made up" cables then, but where do you buy 'Bakers Fluid' these days, haven't seen it in years? Morrag

|

|

|

|

|

Logged

Logged

|

Beware the Ides of March, But!

|

|

|

|

SUMO

|

|

« Reply #2 on: February 04, 2009, 12:46:34 PM » |

|

theres loads of places online - googles your friend. but i got that bottle from a little shop in sowerby bridge called R. & M. Sutcliffe, and a bottle lasts a lifetime [if you dont knock it over - oops], kind of an old hardware / engineering supplies shop.

|

|

|

|

|

Logged

Logged

|

|

|

|

Manky Monkey

Administrator

Hero Member

Karma: 264

Posts: 55102

|

|

« Reply #3 on: February 04, 2009, 05:49:10 PM » |

|

Do you need to "tin" the cable with solder first Sumo? like wiring? We're happy to take Tech features -or any other features, from anyone who wants to write them. As long as everyone's happy with the information given, we'll add them to the archive. As we always say, if we're encouraging people to have a go at this building lark, we should be responsible enough to make sure they're doing it properly & safely. No-one knows everything & even the longest served among us can pick up some useful info.  |

|

|

|

|

Logged

Logged

|

On the last freedom moped out of Nowhere City.

|

|

|

|

SUMO

|

|

« Reply #4 on: February 04, 2009, 05:53:13 PM » |

|

nope you dont want to tin them. that would stop you splaying the ends out when you have threaded it through the nipple.

|

|

|

|

|

Logged

Logged

|

|

|

|

Manky Monkey

Administrator

Hero Member

Karma: 264

Posts: 55102

|

|

« Reply #5 on: February 04, 2009, 05:57:36 PM » |

|

Okey dokey.

|

|

|

|

|

Logged

Logged

|

On the last freedom moped out of Nowhere City.

|

|

|

|

klogan45

|

|

« Reply #6 on: February 04, 2009, 09:17:37 PM » |

|

Hello Sumo, I liked the article. However I thought it said Making Tables   Then I looked again.....must have been a senior moment.   It's given me confidence to have a go when I need to. I might just get some cable etc and have a practice in the workshop at school, just to get the hang of it. It has always seemed like a black art to me and so have never attempted it. Thanks for that. (I always thought that Bakers fluid was something you put in cakes to make them rise.    ) On a more serious note though...How do you cut the cable to lenght without buggering up the end, or stop it unwinding? I know that it sounds like a basic question but not having done this before I would'nt know. The last time I tried this was donkeys (or should that be Monkeys?) years ago when I tried and failed miserably to make a cable for my bicycle. I was about ten at the time. When I tried to cut the cable the bloody thing unwound itself about a foot. (300mm for you young 'uns) Regards K |

|

|

|

« Last Edit: February 04, 2009, 09:25:06 PM by klogan45 »

|

Logged

Logged

|

Confucius say woman who flies upside down has crack up!

He who holds The Angle Grinder of Destiny holds the fate of bikekind in his hands.

Where did that 13mm spanner go then?

|

|

|

|

cunningplan

|

|

« Reply #7 on: February 04, 2009, 10:24:55 PM » |

|

I don't know the proper way, but I use a good but old set of plyers, put the cable in the cutting part, put one side on a hard surface and give it a good tap with a hammer, always gets clean cuts.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

SUMO

|

|

« Reply #8 on: February 04, 2009, 10:57:07 PM » |

|

i have some old military barbed wire cutters that cut it like butter - sorry that doesnt really help...

|

|

|

|

|

Logged

Logged

|

|

|

|

Manky Monkey

Administrator

Hero Member

Karma: 264

Posts: 55102

|

|

« Reply #9 on: February 04, 2009, 11:09:34 PM » |

|

Clamp the cable in a vice & use a cutting disc on an angle grinder.

-see. Told you. People want to know the basic stuff. It might seem blindingly obvious to you, but there'll be someone reading this who wants to know how to do these jobs but doesn't want to look silly by asking -& it's usually me!

|

|

|

|

|

Logged

Logged

|

On the last freedom moped out of Nowhere City.

|

|

|

|

klogan45

|

|

« Reply #10 on: February 04, 2009, 11:13:26 PM » |

|

Thanks guys  T'was me this time MM Regards K |

|

|

|

|

Logged

Logged

|

Confucius say woman who flies upside down has crack up!

He who holds The Angle Grinder of Destiny holds the fate of bikekind in his hands.

Where did that 13mm spanner go then?

|

|

|

Manky Monkey

Administrator

Hero Member

Karma: 264

Posts: 55102

|

|

« Reply #11 on: February 04, 2009, 11:22:42 PM » |

|

Is there a more readily available alternative to Baker's fluid for cleaning the cable? I'm thinking some other fluid or powder we're all more likely to have to hand in the shed -tea maybe! Obviously nothing flamable if you're going to heat it!

|

|

|

|

|

Logged

Logged

|

On the last freedom moped out of Nowhere City.

|

|

|

|

gpz

|

|

« Reply #12 on: February 04, 2009, 11:33:21 PM » |

|

some off the modern fluxs we use for soldering plumbing fittings clean as they are heated whether the heat from a soldering iron would be enough not sure off but the flux can be bought at plumbers merchants

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Chevy Rick

|

|

« Reply #13 on: February 05, 2009, 12:12:20 AM » |

|

You can use spirit of salts to clean an area to be soldered, nice to see bakers fluid in a plastic container, as it used to rot the tins it was sold in before, ive never had any luck with plumbers flux.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

tbone

|

|

« Reply #14 on: February 05, 2009, 11:17:30 AM » |

|

Bakers Fluid used to be diluted hydrochloric acid and a mixture of chemicals, no surprise then when as mentioned, it used to rust the tins it came in! These days, thanks to our enviromentaly friendly pc gone mad world, its not as harsh as it was but still as effective and probably the best `all in one`.

Flux serves 3 purposes when used in the soldering proccess:

Firstly it cleans oxidants (nothing else) from the metals being soldered, Secondly it forms an air tight barrier to prevent oxidants reapearing and thirdly it helps the amalgamation process by allowing the solder to flow easier.

So, in answer to Mr M`s question, YES, something like carb cleaner can be used to remove excess oil/grease from the cable first, this in turn would have to be wiped off before using a soldering flux, and i think its worth mentioning at this point that most DIY solder is now flux cored (it contains the stuff).

|

|

|

|

|

Logged

Logged

|

NO I WON`T. aye ok then, i will

|

|

|

|