I had a broken bolt in the bottom yoke that I had to drill out, needed to save the tread in the yoke if I could so had to drill the broken bit out centrally, only problem is, I'm not that good at doing stuff accurately or straight.

I had a bit of a think an figured if I made a guide for the drill bit then I stood half a chance of getting a straight hole in the broken bolt and saving the thread. So this is what I came up with (excuse the crap photo's, I'm a bit shaky today)

The people in the know, probably know how to do this, but for those that don't here it is.

(Oh, this took me three go's to get right, but with a better pillar drill and some engineering experience you could get it right first time)

First, put your drill bit in the chuck upside down.

Drilling a bolt.

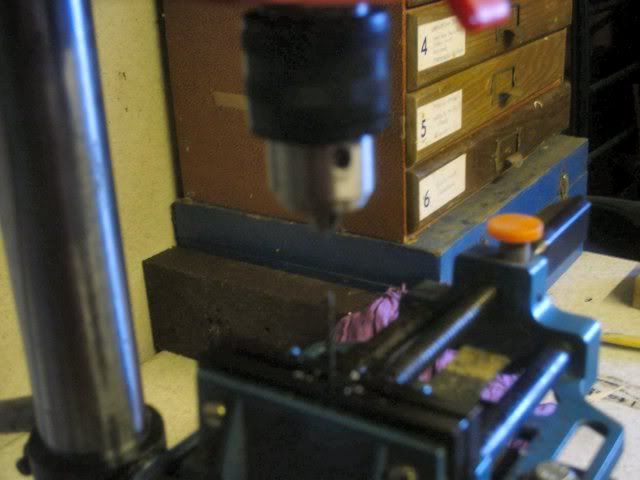

Then, bring the chuck down to your vice and clamp the drill bit in very very tight.

Drilling a bolt.

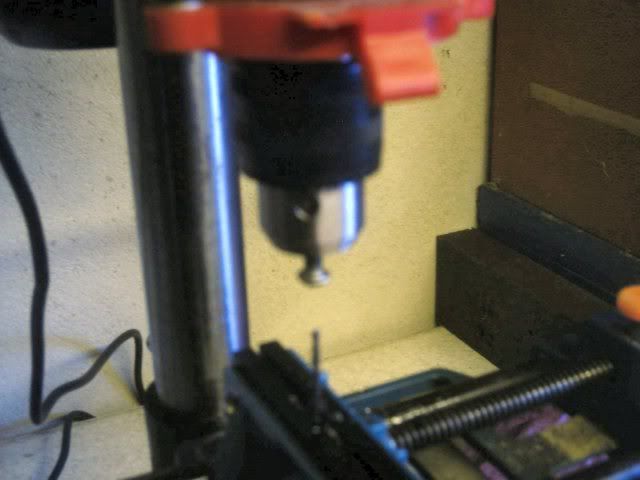

Undo the chuck and lift it up again so the drill bit is in the vice with the sharp bit pointing upwards

Drilling a bolt.

Now, take your chosen bolt ( I guess you could also do this with rod or hex bar) and clamp it tight in the drill chuck. (couldn't get a decent picture of that, so you'll have to imagine)

But you should end up with this.

Drilling a bolt.

Put your drill on the slowest speed and use plenty of oil, I mean lots of oil and use the drill like you normally would. (if you use a really thin drill bit it will vibrate alot and go out of line, so it's a bit trial and error here)

Drilling a bolt.

Eventually though, you should end up with a hole right through the bolt and in theory it should be dead centre ,although mine was a bot off, but it was good enough for what I needed it for. (And the picture is real blurry as well, one hand doesn't hold a camera steady)

Drilling a bolt.

Then I bolted the drilled bolt into the hole until it touched the broken bolt.

Drilling a bolt.

and drilled with a hand drill because I could fit the yoke in my pillar drill.

Drilling a bolt.

Cleaned out the swarf and crud left behind, ran a m6 tap down, just to make sure it was clean and voila, the nice new stainless bolt fit's a treat.

Drilling a bolt.