Manky Monkey

Administrator

Hero Member

Karma: 264

Posts: 55102

|

|

« Reply #30 on: May 04, 2014, 06:04:23 PM » |

|

I cut the neck on a thermostat housing & had it TIG welded back in a different direction to clear a frame tube.

|

|

|

|

|

Logged

Logged

|

On the last freedom moped out of Nowhere City.

|

|

|

|

ROD

|

|

« Reply #31 on: May 04, 2014, 06:35:39 PM » |

|

Im surprised it welded ! Im going to file the lugs down so that Im left with a flat rim round the outer edge, then cut a large 'washer' to sit on the rim and locate it with the existing bolt holes in the head.Must find out if the rad mod is do~able first before I modify anything else.Im considering doing the rad, but I know I'll get into probs with it!  |

|

|

|

|

Logged

Logged

|

|

|

|

Manky Monkey

Administrator

Hero Member

Karma: 264

Posts: 55102

|

|

« Reply #32 on: May 04, 2014, 06:58:16 PM » |

|

Yeah, the welder wasn't too impressed with the casting, but TIGgers are wonderful things.

I sleeved it with a length of tube to keep the 2 pieces straight & true. I guess you could do the same with Chemical Metal instead of welding?

|

|

|

|

|

Logged

Logged

|

On the last freedom moped out of Nowhere City.

|

|

|

|

ROD

|

|

« Reply #33 on: May 04, 2014, 07:11:46 PM » |

|

I did think that as well. Iused it to glue a bleed tube spigot into the housing.Im not taking any chances with it coming adrift though. Im gonna sort this heating prob properly once and for all! ..well, as proper as a custom install can be anyway  |

|

|

|

|

Logged

Logged

|

|

|

|

Manky Monkey

Administrator

Hero Member

Karma: 264

Posts: 55102

|

|

« Reply #34 on: May 04, 2014, 07:21:58 PM » |

|

Engineering skill, patience & sheer bloody mindedness will fix it in the end mate.

|

|

|

|

|

Logged

Logged

|

On the last freedom moped out of Nowhere City.

|

|

|

|

andyrennison

|

|

« Reply #35 on: May 04, 2014, 10:18:59 PM » |

|

I know less than nowt rod, but keep it simple is a good mantra

|

|

|

|

|

Logged

Logged

|

Thousands of candles can be lit from a single candle,

and the life of the candle will not be shortened.

Happiness never decreases by being shared

|

|

|

|

ROD

|

|

« Reply #36 on: May 05, 2014, 07:21:55 PM » |

|

So I bit the bullet today and had a go at modding the rad myself.Not very pretty, but position wise I think it will work.The bottom pipe stub wants to be in the same position as the eng mount, fanbelt , and alt pulley! Going to have to lift the alt by about 10mm, arduous task! The lip on the top edge of the rads bottomtank clears the bottom crank pulley by about 10mm, so its very tight .The top of the rad is level with the top of the stat outlet.I made a ring to clamp the stat housing down, after I moved it through 90 degs, now facing outwards.I think I will cover the rad and all new and old bracketry with a stainless shroud.I'll do away with the bike fan and get a 9" slimline aftermarket one.It all appears to be going into place, but I bet I'll see a prob when I go back to it tomorrow!

|

|

|

|

|

Logged

Logged

|

|

|

|

Manky Monkey

Administrator

Hero Member

Karma: 264

Posts: 55102

|

|

« Reply #37 on: May 05, 2014, 10:21:48 PM » |

|

Grab a photo of it when you do please -my Monkey brain's struggling to keep up with all this!

|

|

|

|

|

Logged

Logged

|

On the last freedom moped out of Nowhere City.

|

|

|

|

ROD

|

|

« Reply #38 on: May 06, 2014, 05:46:59 PM » |

|

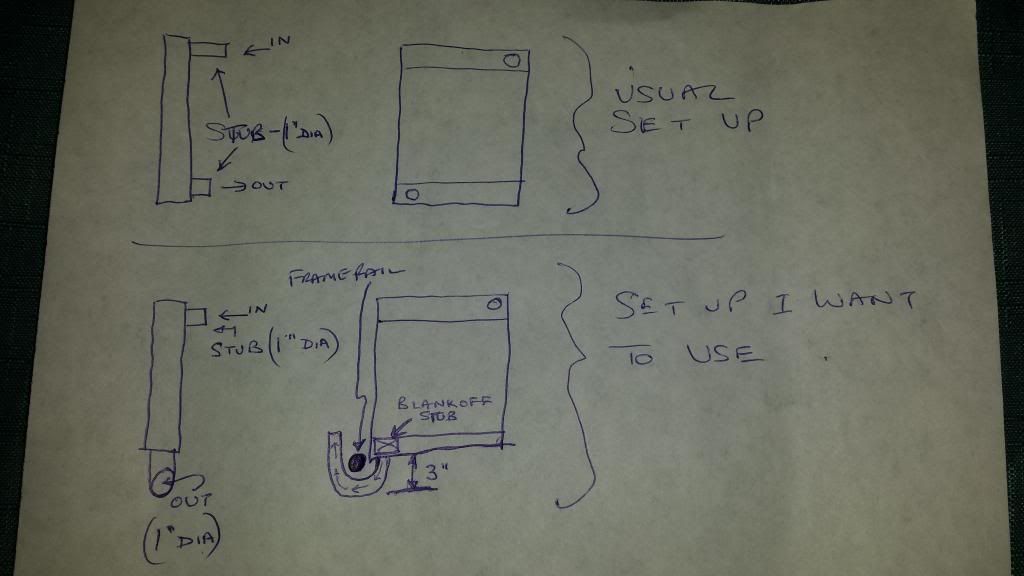

Whats the opinion on this idea please? Is an outlet in the bottom of the tank going to be too much work for the water pump to push the water round? The idea I had of adding a 90 bend to the existing bottom stub wont work as it will hit the chassis rail,so this is my last idea!  fiddling with me waterworks! This pic shows the size of the bend I want to use.The paper is depicting the rad corner.  fiddling with me waterworks! I need thoughts on this asap,as its driving me mad! Thanks Rod |

|

|

|

|

Logged

Logged

|

|

|

|

|

ROD

|

|

« Reply #39 on: May 06, 2014, 07:07:42 PM » |

|

Think I may have solved this (see other thread), but would still apreciate comments pls.

Rod

|

|

|

|

|

Logged

Logged

|

|

|

|

|

ROD

|

|

« Reply #40 on: May 07, 2014, 09:00:29 PM » |

|

Today I blocked off the orig bottom outlet and fitted a new outlet on the end of the bottom tank with a 90 deg elbow facing upward.Got the rad mounted on brackets.Frame and bottom pulley clearances are TIGHT ! Carrying on at first light tomorrow.

|

|

|

|

|

Logged

Logged

|

|

|

|

Manky Monkey

Administrator

Hero Member

Karma: 264

Posts: 55102

|

|

« Reply #41 on: May 07, 2014, 09:08:55 PM » |

|

Dedication, or obsession?!  |

|

|

|

|

Logged

Logged

|

On the last freedom moped out of Nowhere City.

|

|

|

|

ROD

|

|

« Reply #42 on: May 09, 2014, 03:07:15 PM » |

|

So after 2 very long days getting all this rebuilt, recon engine etc etc, I managed to get it fired up today...woohooo!...NOT! Water leak from hole under waterpump shaft, ok not too bad, all other mods werent leaking, so I was pleased....until I saw the emulsified oil in the rad!!!!!

Im guessing headgasket, or POSSIBLY the seal to one of the liners? but everything is new, and Ive been extra careful prepping everything when I did the head.Torque settings are good etc .I really cant be doing this anymore!

|

|

|

|

« Last Edit: May 09, 2014, 03:36:34 PM by ROD »

|

Logged

Logged

|

|

|

|

|

terry t

|

|

« Reply #43 on: May 09, 2014, 03:53:57 PM » |

|

when you done the alterations to the rad, by soldering the blank plate and the new spigot, did you flush the rad out with hot water to clear all the flux residue out

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Olds

|

|

« Reply #44 on: May 09, 2014, 04:32:34 PM » |

|

Are you sure the oil wasn't already in the rad?

Is there coolant in the sump?

|

|

|

|

|

Logged

Logged

|

Getting older but no wiser! Just using bigger hammers.

The answer to most problems, fire and lots of it.

|

|

|

|